A cacao plantation in the heart of the Peruvian Amazon

We are in the upper Amazon basin, the botanical cradle of cacao. In this area, humans and animals consumed cacao in one way or another 5,000 years before we bought our first Fair Trade chocolate bar.

But how did we end up here? My mother is originally from Shapaja, a small fishing and farming village on the riverbank. My parents decided to return to her lush lands in 2012 to grow organic cacao. They now live in an Eden-like garden on the left bank of the Huallaga.

My father likes to remind us that Werner Herzog shot Aguirre, the Wrath of God just below the plantation! A hallucinatory film about 16th-century conquistadors who lose their minds while searching for El Dorado. We think we’ve found it!

Early in the morning the mist still envelops the surrounding forest; we follow my father, cap on his head and machete in hand through the plantation. They named the place Wasi-Manta, ‘of the house’ in Quechua. It is a family-run farm of about ten hectares, where 10,000 cacao trees stand alongside different species of trees, multicolored birds, tiny monkeys and snakes!

We put on heavy Quechua shoes and recycle Quentin’s shirts to make an insect-proof uniform. We always have to more or less watch where we put our hands, because the isulas — giant Amazonian ants, spiders and vipers — are also part of the game.

In the late 1990s, cacao cultivation supplanted that of coca, a stimulating plant whose leaves are used for therapeutic purposes by locals and transformed into white powder by the narcos.

The authorities, in collaboration with the US DEA, had the good idea of promoting an economic alternative to coca to small farmers with the CCN – a cloned cacao. The latter has a high yield, but its aromas are poor. The balance is fragile because cacao can sometimes be less profitable than coca!

At Wasi Manta we take the opposite approach by exclusively cultivating organic criollo, a rarer, more fragrant variety, but less eager to grow!

From the cacao tree to the cacao bean

Under the canopy, the shade, the black soil and the rain

First, the soil. To grow well, cacao needs an organic soil, with lots of things to eat! Five million years ago, the Pebas Sea covered the upper Amazon basin, hence the richness of the soils and subsoils on this land.

It’s called “black earth”. Many leaves, sometimes fruits, litter the ground; this organic matter acts as a natural fertilizer.

Here the plantation is on a slope, at an altitude ranging from 200 to 700 meters. This helps drain the land well, ideal for nourishing the cacao tree’s roots!

Another essential element: rain. We are in a humid forest, where it rains very regularly. Cacao needs a heavy rain to grow, at least once a week.

It is dark under the cacao trees. Other trees, much taller, surround them, feed them and protect them, forming a canopy. This is called agroforestry.

At Wasi-manta they are mostly citrus: orange trees, lemon trees, grapefruit trees, but also banana and papaya trees. All these trees help give the cacao its fruity aroma.

Cacao babies

Cacao trees can be wild, but to develop a plantation, you have to plant small seedlings. These are watered regularly, before becoming fruit trees 2 to 5 years later – it’s better to be patient with the criollo!

Flowers on the bark

Pretty cream-colored flowers grow directly on the trunk. Some, finally, 1 in 1000, are fertilized and become cacao pods.

You can see other things growing on the trunk, the \”chupones\”. They are young cacao shoots that grow directly on the cacao tree and compete with the reproductive part. They must be removed daily!

However, they can also be used to propagate cacao: you let one grow on the original tree, and when that tree dies, you keep only the chupon, and so on.

The magic of the cacao pods

It’s the mythical fruit of cacao, stamped on every bar that claims to be organic or natural, and often used to promote high-quality cacao.

Red, green, yellow depending on the variety, they color the cacao trees and already foreshadow the quality of the beans and, ultimately, the chocolate. From cacao flowers, they grow right on the trunk, sometimes completely vertically, defying the laws of gravity.

But cacao pods never fall on their own!

Right now in the region there is a fungus, moniliasis, that attacks the pods. It happens when it’s too humid. We then have to remove all the damaged pods so as not to contaminate the trees, and quickly harvest the ripe pods. It can be disastrous for producers. Some of our neighbors have given up :(.

Harvesting the treasure

Daisio and Mateo are the plantation’s caretakers. They also harvest the ripe pods and maintain the cacao trees. They are always accompanied by the dogs, who spend most of their time rolling in the leaves.

Beyond its appearance, to know if a pod is good, you shake it. If you can hear something moving inside, you’re good!

The harvest begins in April and continues until the start of the following year. So there is cocoa all year round – but a little less starting in December. The pods we harvest are about 5 months old. If we wait too long, the beans sprout inside the pod and it’s ruined!

The largest pods grow on the trunk and on the big branches. They are also the best because they are overfed! They are harvested with a machete, a knife and a pruner. Then we put them in jute sacks and gather them on the plantation paths.

Majambo, the white cousin of cocoa!

During our visit, we discover the cocoa cousin, the Majambo (Theobroma bicolor). Its pod is much larger and ovoid, and contains flat white beans with an almond flavor. Chocolateries in the region make delicious spreads and bars from it. For us it’s the future of white chocolate!

Opening the pods with a machete

At the end of the harvest day, we split open the pods with a machete: it’s pod cracking. A white substance, the mucilage, envelops the beans. There are between 20 and 50 beans per pod! They cling to the center of the pod, to what is called the placenta.

Inside the pod you also find a tangy and sweet juice, tasting of grapefruit. It’s a characteristic of Amazonian pods. Historically here, cacao was exploited for its pulp and mucilage. Monkeys love it!

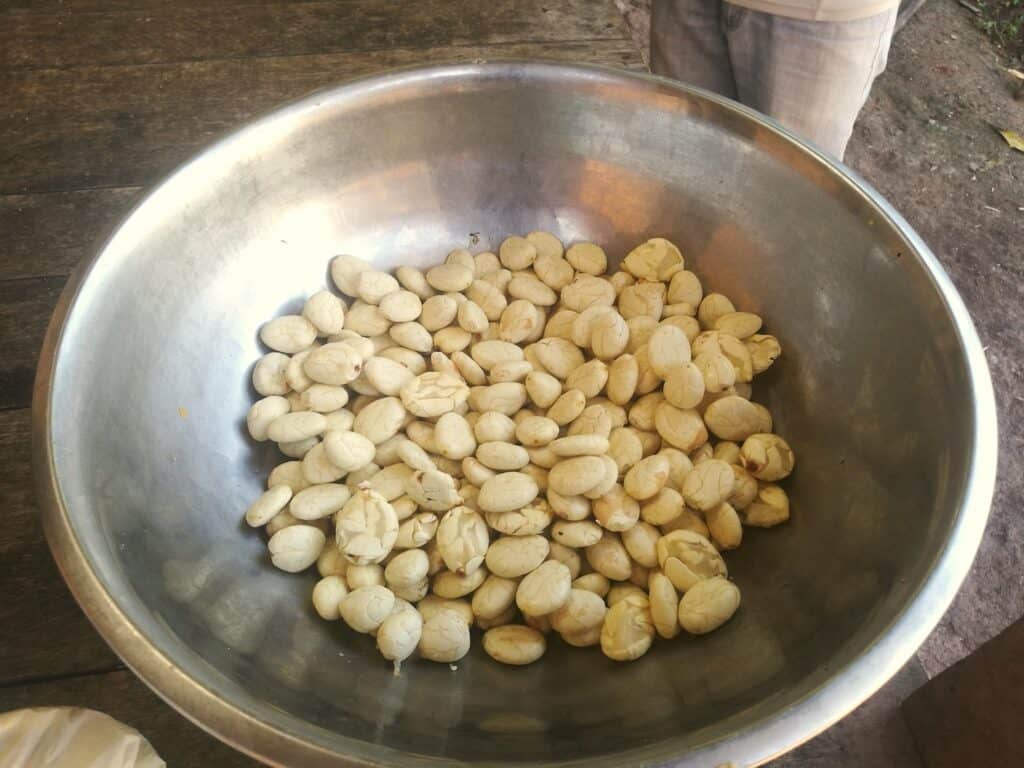

We carefully pick out the beans and sort them, keeping only those that are good for fermentation. Then at night, we let them drain in nets, in order to remove the excess juice they contain.

Fermentation in banana leaves

Fermentation is one of the most delicate steps. It stops the beans from germinating and reveals their precious flavors and nutrients.

The beans are placed in natural wooden boxes lined with banana leaves, with which they are completely covered. The temperature rises to 43°C and the operation lasts about a week.

A strange smell emanates from it. It’s a sign of quality! In high-end chocolate making, beans are selected based on their fermentation percentage. Out of 100 beans, 98 must be fermented.

Drying in the sun

When the fermentation is finished, the beans are dried in the sun on raised drying racks. It’s still the best way to preserve their aromatic qualities and keep them clean. Once they are well dry — after several days, and when their storage capacity is judged optimal, a final sorting is carried out.

And there you go, the beans are ready to be marketed! They are placed in jute bags and brought to our buyers in Tarapoto, the largest city in the San Martín region, or to Lima.

We also keep some for chocolatiers who make bean-to-bar chocolate, meaning they work the cocoa bean themselves to turn it into chocolate. But that’s another story! We’ll tell you about it very soon 😉

Charlotte & Quentin